DVDs / Digital Delivery

Digital Delivery - Available For All Titles

Order and start watching our instructional videos in seconds. There is no waiting for deliveries, no shipping or customs charges, and we never run out of stock. Watch anything that you’ve purchased via digital delivery in a few taps or clicks, and on a variety of supported devices.

Steve Schwarzer - Crescent City, Florida

Steve Schwarzer is an ABS Master Bladesmith working out of Crescent City, Florida. He’s the longest continuous serving Master Bladesmith in the American Bladesmith Society.

Steve started forging blades in 1972, and his Master Bladesmith papers were signed by William F. (Bill) Moran in 1981. Steve’s been making knives for over 50 years now, and during this time he has developed various methods for working with canister and powder welded damascus.

Steve’s many years of experience and in-depth knowledge of forging damascus is on full display in this demonstration. Although the canister pattern that he forges in this video may be somewhat simple, the principles taught throughout the video can be used to produce virtually any other more complex pattern. His knowledge should be of great value to anyone who desires to forge canister damascus.

Alex Ruiz - San Antonio, Texas

Alex Ruiz is a part-time blacksmith and bladesmith from San Antonio, TX. Driven by a love of history and a background in archaeology, he picked up blacksmithing as a hobby in order to connect with old world methods of craftsmanship. In 2018 he competed on the television show Forged in Fire on the History Channel and came home with the title of Forged in Fire Champion (Season 5 Episode 13).

He is a member of Balcones Forge Central Texas Blacksmiths, holds a Lonestar Member rank in the Texas Knifemakers Guild, and is a member of the American Bladesmith Society.

Bill Ruple - Pleasanton, Texas

Bill Ruple is a traditional pattern slipjoint maker living in Pleasanton, TX. He had a career as a peanut farmer but started making knives in 1988. He went into full- time knifemaking in 2002.

He enjoys teaching and has taught many talented knifemakers over the years.

He makes both single and multi-blade knives, but multi-blade folders are the ones he enjoys the most. Bill describes knifemaking as his labor of love.

Craig Brewer - Killeen, Texas

Craig is a full-time knifemaker in central Texas who started making knives in 2002. He later met Johnny Stout and Harvey Dean and started attending a hammer-in they hosted. There he met many other knife makers willing to share information on all aspects of knife making.

Craig credits Bill Ruple and Rusty Preston the most for getting him started on slipjoint knives. Bill and Rusty provided encouragement and instruction to Craig and many other knifemakers. Craig continues to refine his techniques and skills as he focuses mostly on slipjoint and lockback folders.

In this video, Craig demonstrates how he makes a three blade stockman. This is a follow-up to his first video Slipjoints With Craig Brewer.

Please note: Many of the operations covered in the first video are only touched on or mentioned in this one. The primary focus of this video is to demonstrate the steps needed to move from a single to a multi-blade knife.

Tobin Nieto - San Antonio, Texas

Tobin Nieto has been forging in the primitive aesthetic and style since 2002. A student of the neo tribal metalsmith philosophy, he seeks to do much of the work with minimal tooling. He is also a champion from the History Channel’s show Forged in Fire. Mr. Nieto is currently teaching his method of forging in San Antonio, Texas.

with Tobin Nieto

If you want to start forging knives with minimal tools and cost, then this video is for you. Tobin has gas forges, tongs, grinders, and anvils, but does he use them in this video? No! What he does use are tools and supplies that can be picked up at your local scrap yard, thrift shop, and big-box store.

In this video, Tobin forges one of his primitive style knives from an old car spring, and he finishes it off with a cord wrapped handle.

Derek Melton - Clinton, Mississippi

Derek Melton is a part-time blacksmith & bladesmith who is currently located in Clinton, Mississippi. He’s been working with wood and metal for most of his life, and he’s been making knives and other items from metal since 1999. Having a love for the forged blade and a keen eye for detail, Derek took his skills to television in 2018 and appeared on an episode of the hit History Channel show “Forged in Fire”. He competed for and won the title of “Forged in Fire Champion” on episode 21 of Season 5.

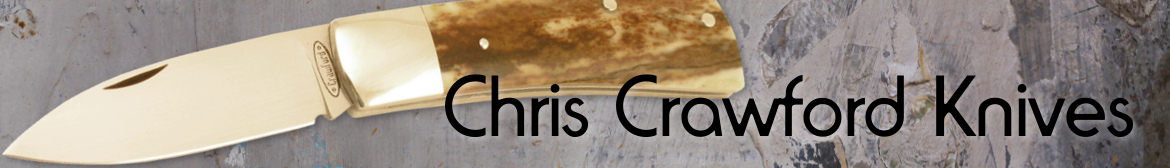

Chris Crawford - Saltillo, Mississippi

In early February of 2001, a friend of mine sent me to a web site that showed how to make a knife with hand tools. Using that tutorial, I completed my first knife in mid February. It was a very basic skinner with oak scales.

I now primarily make folding knives, and my specialty is building slipjoints. I've always liked the traditional patterns, and there's nothing like the walk-and-talk of a knife with a good strong spring.

with Chris Crawford

This is an updated version of the DVD "How to Build a Scale Release Automatic" that I released back in 2002. While most of my techniques have not changed, today's technology has allowed me to release a higher quality product. I originally put this video together because of the lack of information that is available in the area of building automatic knives.

with Chris Crawford

In this video I build an automatic based on the general design of my EDC-1 slipjoint pattern. The knife uses a leaf spring to throw the blade, and it uses a lever to fire it. I pretty much design the knife on the fly, and while this may not be the best method, the viewer should benefit from seeing what works and what does not.

Allen Elishewitz - New Braunfels, Texas

Allen Elishewitz is a Texas knifemaker who became interested in knives at a very young age. His many years of training in the different martial arts, along with his experiences as a Recon Marine, have given Allen the perfect background to design both defense and utility knives.

Allen started making knives part time while he was in college studying Criminal Justice and Fine Arts, and he decided to become a full time knifemaker after graduating. He’s been making knives since 1988, constantly researching, refining, and developing the craft.

with Allen Elishewitz

In this video Allen shows how he designs his tactical folders. Not only does Allen show how to design, but he also stops to talk about the theory behind why he does it the way he does. Some of the techniques demonstrated will be applicable to many other types of folder designs.

with Allen Elishewitz

In this video Allen builds an advanced tactical folder from start to finish using advanced tools and techniques. If you want to know how Allen builds his knives from day to day, this is the video that shows it. This video focuses on the building process and does not cover pattern design.

with Allen Elishewitz

In this video Allen teaches ten different embellishment techniques that you can use to take the look and presentation of your knives to the next level. We can define an embellishment as anything that adds design interest to a piece, and the techniques demonstrated here do just that.

J. Neilson - Towanda, Pennsylvania

James (J.) Neilson is an American Bladesmith Society Mastersmith who works from his "shop in the woods" in the endless mountains of northeastern Pennsylvania. There, he has been able to develop his longtime interests in knife making and forging into more than just a hobby. The quiet setting and scarcity of neighbors has been the perfect background to allow J. to develop his skills. He puts a great deal of effort into his wares, and he takes considerable pride in the finished products he produces.

In this video, J. demonstrates how to build a hidden tang hunting knife with a guard. Expanding on the principles taught in the DVD Basic Hunters, J. spends less time talking about forging and grinding and more time showing how to achieve an excellent fit between your hidden tang, guard, and handle.

John Cohea - Nettleton, Mississippi

John Cohea was a frontier style knife maker and leather worker from Nettleton, Mississippi. He always loved anything old, whether it be furniture, cars, antiques, ect. So it was only natural for him to specialize in knives, tomahawks, and leatherwork that reflect that interest.

Luke Swenson - Plummer, Idaho

Luke Swenson is a traditional style folder maker out of Plummer, Idaho and has always been a knife guy. He started out making fixed blades in 2002 but eventually found his way to Bill Ruple’s shop and to his true knifemaking passion which is making traditional slipjoints, multi-blade folders, and lock backs.

Paul Long - Kerrville, Texas

Paul Long started working with leather while attending Texas A&I back in 1951, and it remained a hobby of his until he retired in 1995. After retirement, Paul trained with a master boot and saddle maker for a year. This gave him a good foundation for taking his leather work into almost any direction. In 2004, Paul was asked to make some sheaths for a friend of his who made knives, and the rest is history. Now Paul specializes strictly in knife sheaths, and with nearly 60 years of experience in working with leather, he has become one of the leading sheath makers of our nation.

with Paul Long

Paul Long specializes strictly in knife sheaths, and with nearly 60 years of experience in working with leather, he has become one of the leading sheath makers of our nation. Watch Paul as he builds a pouch sheath from start to finish. In this DVD Paul explains the materials used, the tools used, and the sheath making process in detail.

with Paul Long

Paul Long specializes strictly in knife sheaths, and with nearly 60 years of experience in working with leather, he has become one of the leading sheath makers of our nation. This DVD expands on the techniques covered in Paul’s first DVD, Basic Pouch Sheaths. While you will get to watch Paul build a more complex sheath from start to finish.

with Paul Long

Paul Long specializes strictly in knife sheaths, and with nearly 60 years of experience in working with leather. In this DVD, Paul builds three folder sheaths from start to finish. He builds a flap sheath, a pocket sheath, and a pouch sheath. In addition to the three folder sheaths, Paul also demonstrates how to inlay an exotic skin into a sheath.

with Paul Long

This DVD is a supplement to Paul’s first two sheath DVDs. While Paul does not construct a finished sheath in this DVD, he does take the time to answer some viewer questions, demonstrate some advanced tooling techniques, and give valuable leather working tips that are a result of his many years of experience.

Ray Kirk - Tahlequah, Oklahoma

Ray Kirk is a Master Smith in the American Bladesmith Society, a Forged In Fire Fan Favorite, and an all around nice guy, who forges blades right outside of beautiful Tahlequah, Oklahoma.

Ray started forging knives in 1989. He did stock removal for a while, but he now primarily forges. He forges most of his knives from 52100 round bar.

Chad Nichols - Blue Springs, Mississippi

Chad Nichols is a knifemaker working out of Blue Springs, Mississippi. He specializes in making high quality Stainless Damascus , Carbon Damascus, Mosaic Damascus, Moku-Ti, Zirku-Ti and Mokume.

with Chad Nichols

I had the opportunity to spend the day with Chad Nichols and watch as he demonstrated how to forge weld mosaic damascus. This DVD covers the steps involved in making mosaic bolsters. In addition to the geometric mosaic pattern that is created in this DVD, Chad also explains and demonstrates how to prepare a Spider Web mosaic can.

Weldon Whitley - Odessa, Texas

Weldon began making knives for the public in 1965. With a background in machining, he has been able to apply many of his machining skills to the trade of knife making. Weldon does his own embellishments to include engraving, scrimshaw, and file work in an effort to be the sole artist on his work. He and his wife Doris reside in Odessa, Texas where he now works as a full time knife maker.

Bruce Evans - Boonville, Mississippi

Bruce Evans is a knifemaker in Bonneville, Mississippi, who makes everything from tomahawks to replication bowies.

with Bruce Evans

I had the opportunity spend a day in Bruce Evans’ knife shop, and I watched as he forged out a spike tomahawk from a round bar of 5160 spring steel. I was so impressed with the process that I wanted to go back and document him as he forged out another one. This time I took my mini-dv camera with me, and as a result, I was able to produce this DVD.